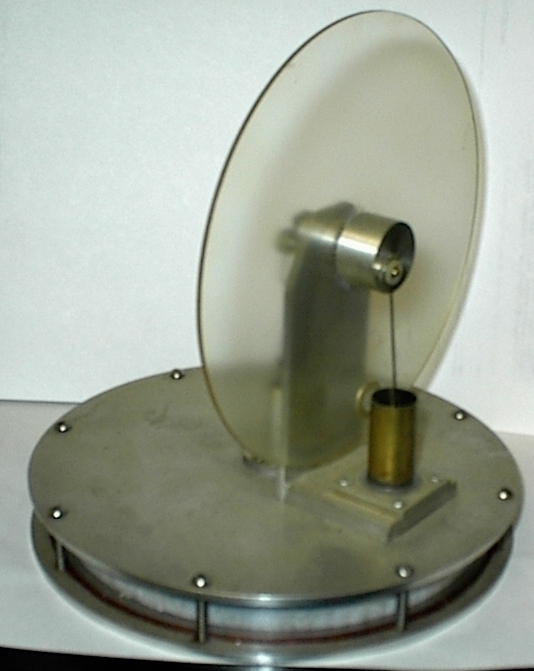

A Stirling engine is a simple mechanism that uses cycle compression along with different gasses to convert heat energy into mechanical energy. Most of the components in this project will be scrap materials, so they should be easy to source thus making the project simple and cost effective. Use the guidelines below to build your own stirring engine.

Tools required

- Glue (high temperature)

- Utility knife

Materials required

- Coast hanger

- Coke and red bull tins

- Balloon

- Bolt

- Straight pins

Instructions

- The first step is constructing the ring stand; this is made from the coke tin. Take the coke tin and use the knife to cut out the bottom to make it hollow then cut it into 2 halves. Use the bottom half with the base ring and cut open the sides of the can to make it into a ring with three legs. The sides of the can have to be cut and bent to form a ring stand.

- After this, you need to make a pressurized vessel. Take another Coke can and take off the sides and cut the top section with a knife to make it into a vessel. Take another Coke tin and cut it about 2 inches from the bottom and put a hole in the center with a pin, then glue the bolt and small rectangular steel plate on the inner center of the top portion to prevent leaks. These components form the pressure vessel.

- Now use a red bull tin to make the displacer as you did with the pressured vessel. Then fit the displacer into the pressure vessel to secure that any leakage is stopped.

- Cut a piece of the crankshaft to create the coat hanger. Punch a hole in two red bull tins and set them aside. Set the crank onto the supporting component so the crank rotates smoothly. Then use the glue to attach it to the pressure vessel.

- Cut a balloon into the shape of a disc which will be used as a diaphragm. The diaphragm will connect the crank and the disks together to strengthen them so that while it is rotating it won’t get damaged.

- To operate the Stirling engine all you have to do now is heat up the base section of the pressure vessel for about half a minute, then push the flywheel and then the wheel will start to spin. However, you will constantly keep cooling the pressure vessel to prevent it from overheating.

Tips and Warning

- Be extra cautious when using the knife to cut the tins, both the knife and the tin edges can accidentally cut you and cause harm.

- You can use ice and put it on top of the vessel to ensure the stirring engine mechanism doesn’t overheat. However, monitor it so that water does not seep in because this will mess up the entire course of action.